Rim features:

ROCKYROAD 36C DISC Clincher Tubeless Ready

UD carbon, matt finish with shiny decals

Hooked design rim, allows the use of tubeless ready tires or standard clincher tires with tubes

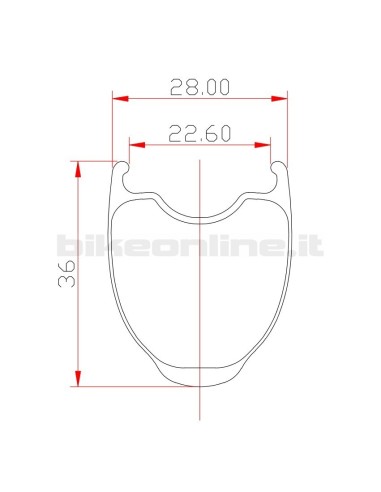

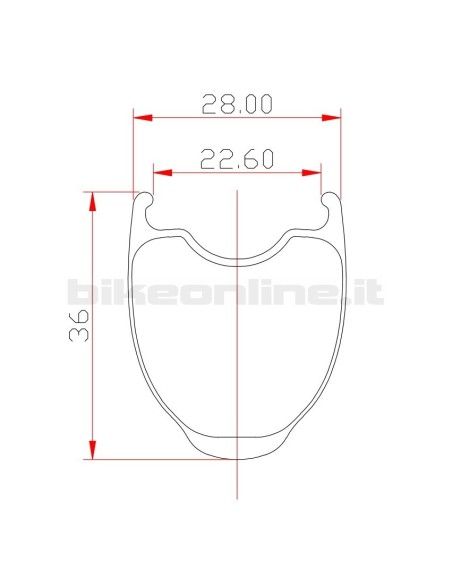

Height: 36mm

Width: 28mm

Internal width: 22.6mm

Weight: 345g

The special layering of the T800 carbon fibre sheets gives ROCKYROAD rims a high lateral stiffness, while ensuring a high shock and vibration dampening capacity, combined with extremely low weights.

Asymmetric design: ensures a significant increase of stability and lateral stiffness of the wheel thanks to a more balanced spoke tension between the two sides of the wheel

Tubeless ready: tubeless convertible with specific tape and valves

ROCKYROAD rims must pass the stringent tests EN 14766 and ED 14781. These tests have been designed to ensure the strength and durability of individual parts as well as of the bicycle as a whole, demanding high quality throughout and consideration of safety aspects from the design stage onwards.

ROCKYROAD rims are intended for Road

Crash replacement policy: in case of accidental break of a ROCKY rim, not covered by warranty.

Hubs features:

EXTRALITE Cyber SPD-3 DISC.

Front thru axle 12x100mm, QR 100mm quick release, convertible.

Rear thru axle 12x142mm, QR 135mm quick release, convertible.

Bearing options: Enduro ABEC 5, ABI Enduro 440-inox, HDC Ceramic, XD15 Ceramic.

Compatibility: Shimano Road 8/9/10/11 / 12S, Sram XD / XDR Drive, Campagnolo 9/10/11 / 12s.

Made of ergal 7075.

Straight-pull flanges.

International Standard 6-hole disc fixing.

Black anodized color with laser graphics.

Made in Italy

Weight: 66g + 146g

Spoke features:

ALPINA BLADE HYPERLITE offer a significant weight saving with no loss of resistance, stiffness of the wheel and durability of the spokes

Section: 2.0-0.9/1.6-2.0mm (bladed section is 0.9 x 1.6mm)

Black colour

Every wheelset is supplied with 3 spare spokes/nipples

Nipples: DSN ergal acid green, black, blue, gold, green, orange, red or silver

Not supplied with quick releases

Our wheels are built by hand in house by highly specialized personnel.

The Bikeonline staff uses the best professional tools on the market into each step of the wheelbuilding process. The P&K Lie truing stand is one example, it allows us to check perfect truing through precise decimal comparators (0.1 millimeters accuracy).

We build most of the tools we use, to fit the level of our builds, which require a high accuracy.

The use of different tensiometers as Park Tool, Pillar and DT Swiss allows us to reach the correct tensions of every spokes.

Each wheel is pre-stressed by hand to ensure that nothing has been settling during the early stages of use and that the spoke tension remains constant for a long time even under very high loads.

This product is to be considered produced on request / on order, due to the high customization needed. It is therefore not possible to use the right of withdrawal or the cancellation of an order already confirmed.

See "Terms and conditions of use". Advance payment is required on this product.