Berd spokes are made from an advanced polymer called Ultra High Molecular Weight Polyethylene (UHMWPE).

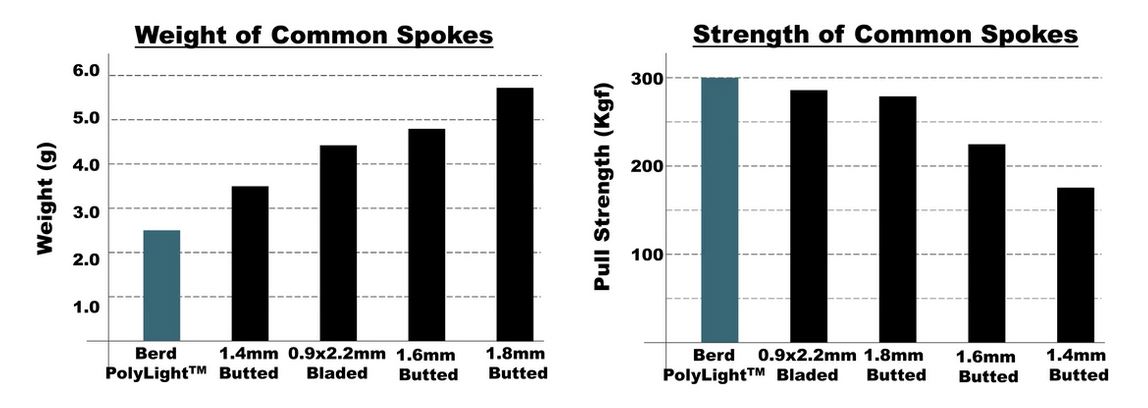

UHMWPE has 12 times the strength-to-weight ratio of steel and floats on water.

Berd spokes have an improved fatigue life over steel and are impervious to the elements. This is what makes Berd spokes the lightest, strongest, and most durable spokes ever invented.

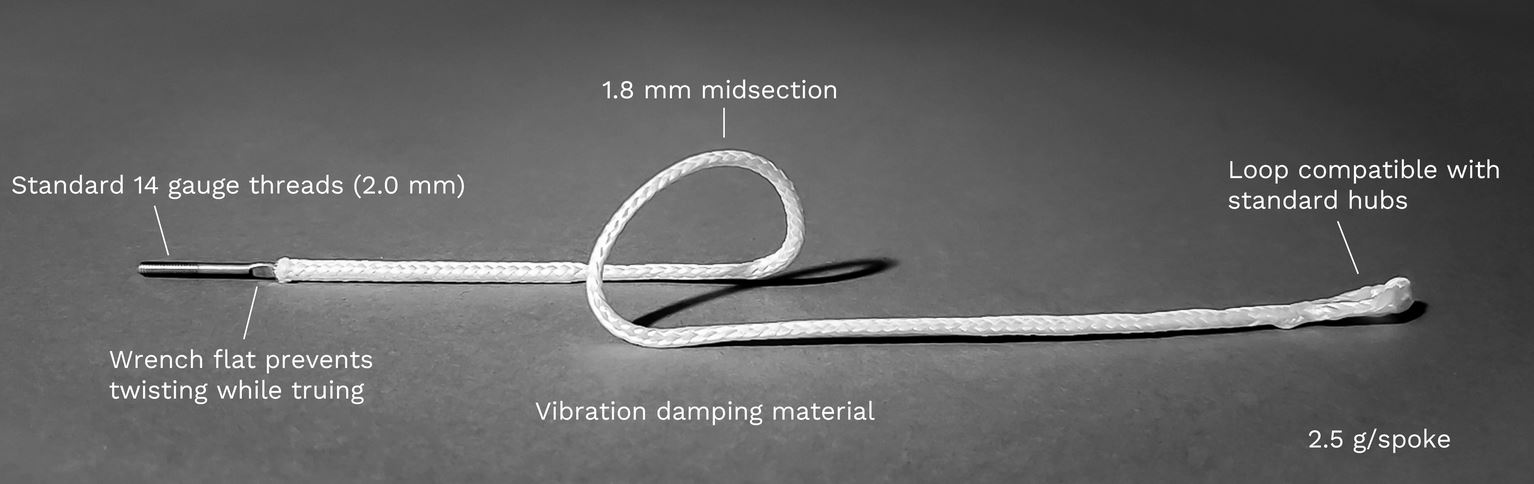

Berd spokes use 14 gauge threads to connect to standard nipples the same way metal spokes do.

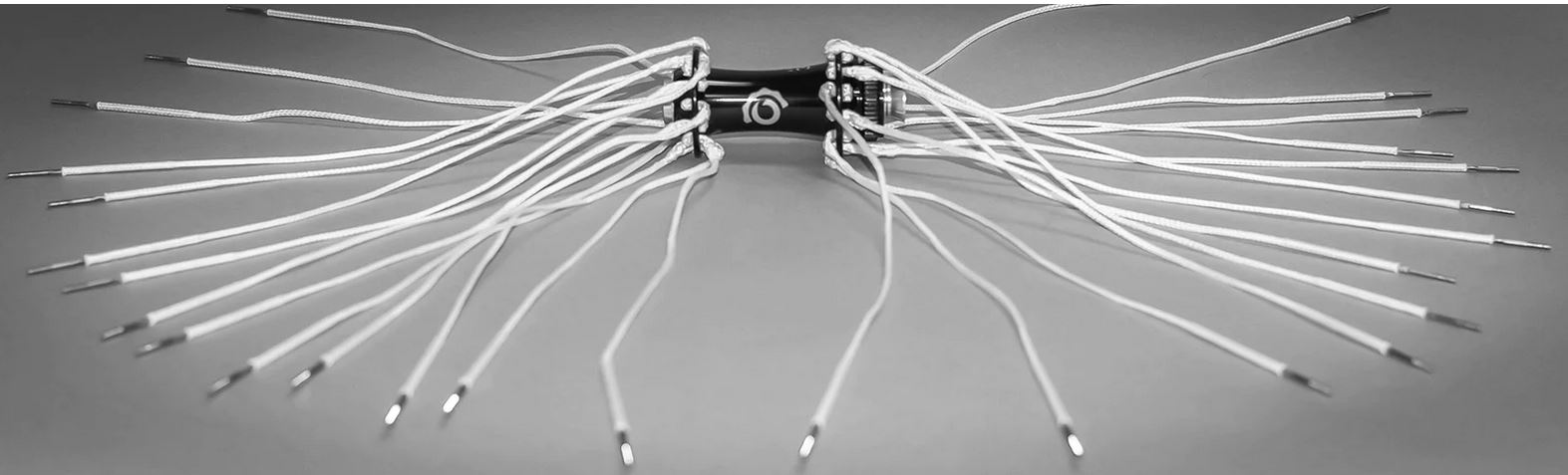

Opposite the threads is a loop, which is pulled through the hub hole and secured with a rod.

Berd spokes feature a 1.8 mm diameter in the midsection and are 2.5 grams per spoke

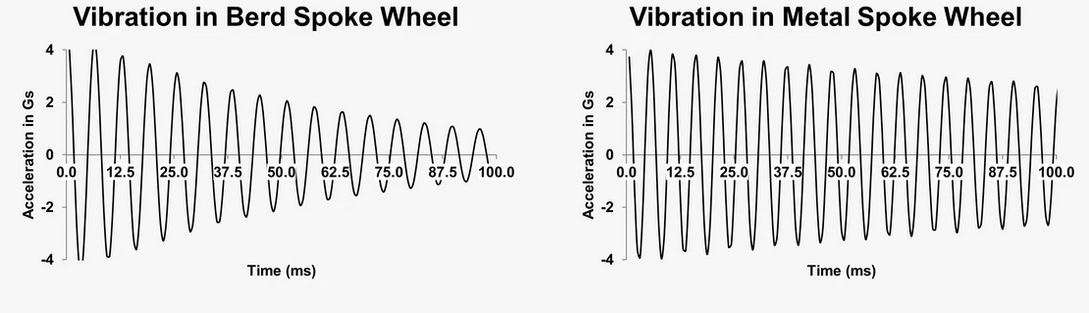

Berd spokes also damp vibrations much more effectively than steel spokes. This results in a more comfortable, smoother, ride. The graphs above demonstrate that wheels with Berd spokes provide 200% better vibration damping than wheels with metal spokes.

Berd spokes work with all J-bend and most straightpull hubs. The spoke is connected to the hub by pulling the loop through the hub hole and inserting a rod into the loop. Once this is done, the spoke cannot pull back through the hub hole.

Wheels built with Berd spokes perform better than steel spokes when subjected to impacts.

This is due to how Berd spokes distribute the impact energy across more spokes, which causes lower stress in the rim, spokes, hub, and nipples.

In the video above, the first impact is a metal spoked wheel with a 101 Joule impact.

Two spokes pull through the rim in this test resulting in the need to replace the whole rim and spokes.

In the second impact, a wheel with Berd spokes (same type of rim, hub, and nipples) is subjected to a 116 Joule impact, which is over 10% more than the metal spoked wheel, but no damage occurs.

This demonstrates the robustness of Berd spokes and wheels to impacts.

Berd spokes also excel in torque fatigue performance due to the material properties of UHMWPE.

The torque fatigue test is an accelerated test to evaluate long-term wheel performance related to both pedaling and braking.

In this test, we apply 250 Nm of torque (much more torque than wheels are subject to during riding) for tens of thousands of cycles. This test is one of the best tests to evaluate spokes and hubs for long-term reliability.

All new Berd wheels undergo this testing during the development phase. An example of this in real life riding: 30 miles per hour and a power of 1,000 W, a wheel will see only 25 Nm of torque.

Berd spokes also resist damage from blunt force impacts made directly to the spokes.

In the slow motion video above, a metal rod is shot into a wheel spinning at high speed to simulate a stick or other object that could be encountered on the trail.

In the metal spoked wheel test, one spoke completely fails by pulling through the rim, which would require full rim replacement, while another spoke is badly bent. In the wheel built with Berd spokes, no damage occurs as the spokes absorb the impact.

Just another way Berd spokes keep you on the trail.

Frequently Asked Questions

What are Berd Spokes made of?

Berd spokes are made from an advanced polymer called ultra-high molecular weight polyethylene (UHMWPE). UHMWPE has 12 times the strength-to-weight ratio of steel and floats on water. It also has a significantly improved fatigue life and will not degrade from UV exposure.

What types of hubs do Berd spokes work with?

Berd spokes are compatible with all J-bend hubs and all tangential straight pull hubs. Berd spokes are not compatible with radial straight pull hubs. Berd spokes are not recommended for use with hubs with carbon hub shells. The Berd Spoke Calculator cannot calculate unique lacing patterns (2:1 lacing, paired spokes, etc.).

What types of rims do Berd spokes work with?

Berd spokes work with all standard bicycle rims, including rims designed for both external and internal nipples.

Do you make BMX spokes?

You betcha! We now offer spokes from 178 mm to 315 mm! Please note, all wheels using spoke lengths from 178 mm to 249 mm require an additional step in your hub preparation as described in the Berd Spokes Installation Guide.

Is there a weight limit for Berd spokes?

There is no weight limit for Berd spokes but, like with any spoke, heavier riders should use more spokes. There may be weight limits for our stock wheelsets, but that is due to rim limitations, not the spokes. Please see the individual product for these listings.

What is the fatigue life at the spoke/nipple interface compared to standard spokes?

Berd spokes typically outperform high-end steel spokes in accelerated drum fatigue tests.

How do your spokes hold up to lateral impact/force?

Berd spokes handle lateral impacts very well! Check out this review from our friends at Worldwide Cyclery for a video example of a lateral impact on the spokes.

How do Berd spokes handle chain drops and derailleurs into spokes?

Chain drops due to over shifting where the chain falls between the cassette and the hub can cause damage to Berd spokes, which may require replacement of the damaged spokes, similar to metal spokes. In other scenarios, such as a derailleur going into the spokes or other blunt force impacts, Berd spokes are often more resilient than metal spokes.

Where can I go for routine maintenance of my Berd wheels?

A Berd dealer near you can be found using our Dealer Locator. Trueing and tensioning may be performed by a trained bicycle mechanic who has read and understands the Berd Installation Guide. If a shop is not a Berd dealer, tools and spare spokes are available from major bicycle parts distributors, including BTI.

Can I race with Berd Spokes?

Yes! Berd spokes are legal for racing. In fact, the UCI, which regulates professional cycling, has specifically approved Berd spokes, so you can race Berd spokes from local crits to the Tour de France. Send us a postcard!

Why are Berd spokes white?

White is the natural color of the material. Like carbon fiber is black, UHMWPE is white.

Do you offer spokes in any color other than white or black?

Berd offers only white and black spokes. However, the spokes can be easily colored by using one of our Spoke Coloring Kits and coloring your white spokes that are installed in Berd wheels.

How white will my white spokes stay over time?

Your spokes will stay pretty white. Over time you may see some staining from dirt, mud, etc. but the UHMWPE is not like white bar tape! You can clean your spokes using Dawn Dish Soap and water, along with some elbow grease. Do not use harsh solvents or cleaning supplies on your spokes. If this is a big concern, we suggest ordering black spokes or using one of our Spoke Coloring Kits to color your spokes.

How much weight will I save over metal spokes?

Depending on the wheelset, weight savings with Berd spokes typically range from 100 to 200 g.

How aero are Berd spokes?

The aerodynamics of Berd spokes are similar to 14-gauge spokes but they are not as aero as a bladed spoke. The weight savings and vibration damping will outweigh this small decrease in aerodynamics for most riders.

Are Berd spokes the same length as metal spokes for any given wheel?

No. Berd spoke lengths are slightly different than metal spoke lengths to account for the hub connection and the initial stretch of the spokes when building. Our spoke calculator must be used to calculate the proper length.

Berd Spokes are flexible, so how can you make a wheel out of them?

To answer that question, we need to discuss how wheels are built. Each spoke in a wheel is pulled in tension during the wheel building process – in fact, each spoke is under 50 - 100 kgf, depending on the particular wheel build. When riding the bike, spokes at the bottom of the wheel de-tension to support the weight of the rider, but because they are pretensioned, they never leave tensile loading. Because of this, flexible spokes function equivalently to metal spokes.

Are wheels built with Berd spokes as stiff as wheels built with traditional metal spokes?

Wheels built with Berd spokes are slightly less stiff than metal spokes when measured statically. As wheel speed increases, the viscoelastic properties of the UHMWPE cause the wheel stiffness to increase the faster you go.

Because Berd spokes are made from a flexible fiber, do they shrink or expand?

Berd spokes do experience viscoelastic stretching during the build process where they will initially lose tension after being brought into tension for the first time. Once the wheels have been properly built and tensioned they will stabilize.

The molecular properties of UHMWPE are unique when it comes to handling individual spokes. If you were to take a spoke out of the packaging and manipulate it, or if you were to lace the spokes into a wheel and then remove the spoke, that spoke would measure slightly shorter than its true length. After tensioning, the spoke will again measure its actual length.

Does my hub need to be modified to work with Berd spokes?

Tangential straight pull hubs do not require hub prep; instead, the Tangential Straight Pull Inserts are used. J-bend spokes require the hub preparation process described in the Installation Guide to remove sharp corners prior to lacing the spokes.

How do Berd spokes connect to the hub?

The eye of the spoke is pulled through the hub hole and secured with a small rod.

How do Berd spokes connect to the rim?

Berd spokes connect to the rim using standard 2 mm, 14-gauge threaded nipples.

What type of nipple should I use with Berd spokes?

We highly recommend using 16 mm double square locking nipples because they can be trued from the back of the rim, have additional thread engagement, and prevent loosening of the nipples over time. If using a rim that requires internal nipples, we recommend locking internal nipples.

Can I use a Single Wall Rim with Berd Spokes?

Berd does not recommend using single wall rims (with the exception of Hed Carbon Fat Bike Rims). Berd spokes must be built with double square nipples due to the elongation that takes place during the build process. As a result, the heads of the nipples cannot easily be taped and sealed for tubeless setup. All single wall wheels built by Berd will be assembled using neoprene washers and brass nipples, which has been tested to be tubeless compatible for Hed Carbon Fat Bike Rims. However, Berd makes no guarantee as to tubeless compatibility on any other rims, which is why Berd does not recommend using single wall rims with Berd spokes.

How do I keep Berd spokes from twisting as I build or true my wheel?

Both the Berd Wheel Builder’s Kit and Berd Spoke Replacement Kit include a Berd Spoke Holding Tool that allows you to grasp the flat that has been manufactured into each Berd spoke, allowing you to hold the spoke while tightening the nipple, much like standard bladed spokes. See this video on How to True a Berd Wheel for more info.

Do Berd spokes lose tension over time, and what maintenance is required?

All wheels with Berd spokes are built with a multi-day tensioning process to reduce the amount of tension loss that will happen after the wheels are installed on a bike. Despite this, the tension in Berd spoke wheels will decrease by approximately 30% over the first 6 months of use due to the natural "bedding in" process of the fibers. This loss in tension does not affect the durability or longevity of Berd spoke wheels, and there is no requirement to increase the tension. The stiffness of the wheels is weakly dependent on spoke tension, so the tension of the wheels may be increased after 3-6 months, if desired, to increase the wheel stiffness by approximately 10%. This is accomplished by turning each nipple by 2 full turns from the tire side of the nipple while using the Berd spoke holding tool to prevent the spokes from twisting, followed minor adjustments to ensure the wheel is true and dished properly.

What are the tension and trueness specifications for new Berd wheels?

At Berd we strive to deliver the highest quality products and wheel builds. We true our wheels to within .50 mm radially, .25 mm laterally, and within .50 mm for the dish. The tension specification for finished Berd wheels is 70 kgf. Berd spokes will lose approximately 30% of their initial tension over the first six months but unlike metal spokes they maintain all of their strength regardless of tension and increasing the tension is not required. This is a normal process and a trained bicycle mechanic can bring the tension back up to 70 kgf or higher tension if desired.

I ordered black spokes but when I measure them, they measure about 1mm shorter than the length ordered. What gives?

When white Berd spokes are colored black they “shrink” by approximately 1 mm. When they are put under tension, they “grow” to their actual length. It is always helpful to lace the high tension of the wheel first and then the low-tension side to accommodate for this slight “shrinkage.”

Can you replace a spoke without removing the nipple?

Similar to metal spokes, a good condition, in-tact, nipple may be used when replacing a spoke in an emergency. However, it is recommended that new nipples be used when replacing spokes.

Can I send my wheels to Bikeonline to rebuild with PolyLight Spokes?

Absolutely! Use our Berd Wheel Rebuilding service for instructions and cost.

Is there anywhere that Berd won’t ship?

We ship wheels and spokes almost everywhere in the world except for areas covered by exclusive dealers or current trade embargos.