The ROCKY KOM 28A rims close the performance gap between carbon and aluminium, with a low weight that's competitive with most carbon rims with these dimensions.

Our aluminum alloy is produced and drawn in Germany and wisely worked in Italy, where the rim is created by a straight bar, then subjected to the Shot Peening process which reduces the surface tensions of the material due to the processing, improving fatigue resistance and durability, and finally anodized and laser etched.

Rim features:

ROCKY KOM 28A 29er

This rim is built for cross country.

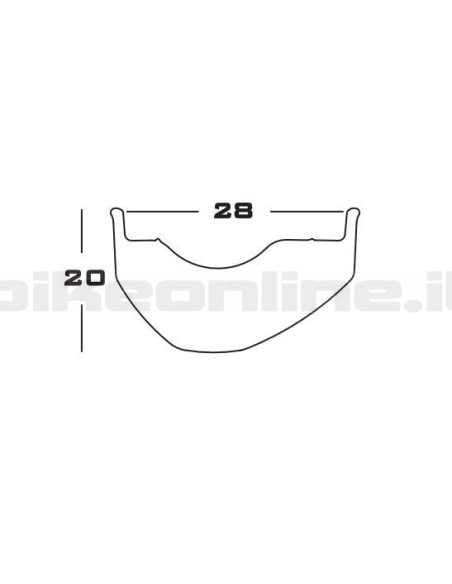

The asymmetric design allows to remarkably reduce the spoke tension difference between the two sides of the wheel, with a big advantage of lateral stiffness and stability.

The special inner profile makes the rim easily tubeless convertible using specific valves and tape, not included in the sales kit.

Matt black anodized aluminium 6000 T6

Aeronautic Surface Treatment (AST) eliminates surface tensions of the material, increasing the resistance.

The asymmetric design allows to remarkably reduce the spoke tension difference between the two sides of the wheel, with a big advantage of lateral stiffness and stability.

Hookles design

Suggested tubeless tape width: 29mm

Max pressure: 3.0 Bar

Tubeless ready

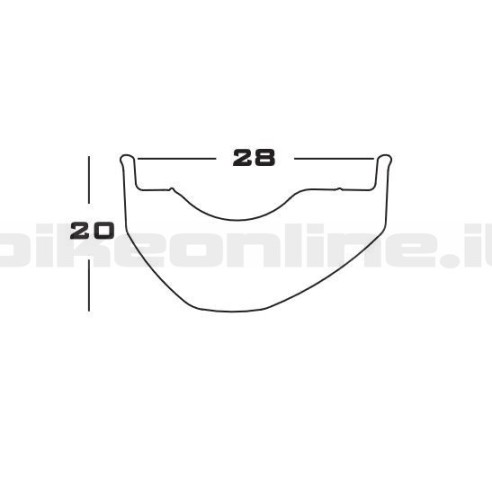

Height: 20mm

Width: 31mm

Internal width: 28mm

Number of spokes: 28

Hub features:

DT Swiss 240 EXP SP 6 Holes

Straight pull hubs made in ergal 7075

36-tooth Star Ratchet EXP engagement system

Black colour

Disc fixing 6 holes

Weight: 120g + 209g

Spoke features:

ALPINA BLADE HYPERLITE offer a significant weight saving with no loss of resistance, stiffness of the wheel and durability of the spokes

Section: 2.0-0.9/1.6-2.0mm (bladed section is 0.9 x 1.6mm)

Black colour

Every wheelset is supplied with 3 spare spokes/nipples

Nipples: DSN ergal

Not supplied with quick releases

Our wheels are built by hand in house by highly specialized personnel.

The Bikeonline staff uses the best professional tools on the market into each step of the wheelbuilding process. The P&K Lie truing stand is one example, it allows us to check perfect truing through precise decimal comparators (0.1 millimeters accuracy).

We build most of the tools we use, to fit the level of our builds, which require a high accuracy.

The use of different tensiometers as Park Tool, Pillar and DT Swiss allows us to reach the correct tensions of every spokes.

Each wheel is pre-stressed by hand to ensure that nothing has been settling during the early stages of use and that the spoke tension remains constant for a long time even under very high loads.

This product is to be considered produced on request / on order, due to the high customization needed. It is therefore not possible to use the right of withdrawal or the cancellation of an order already confirmed.

See "Terms and conditions of use". Advance payment is required on this product.