Rims features:

DUKE 29" Lucky Star HD 6TERS in aluminum is light, stiff and very high quality.

Duke selects the materials used very carefully in order to offer the best possible product.

Intended use: Cross Country, Trail

Material: aluminum

Rim Type: Clincher (clincher and folding)

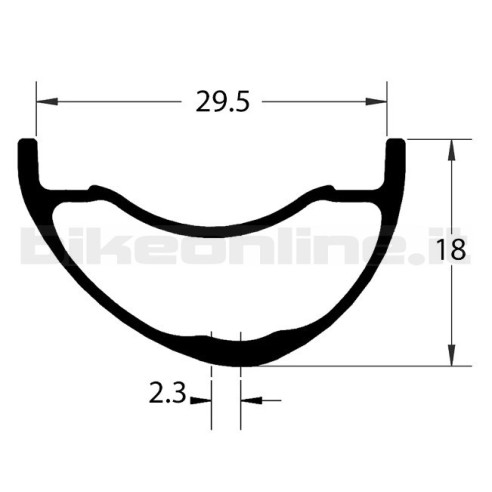

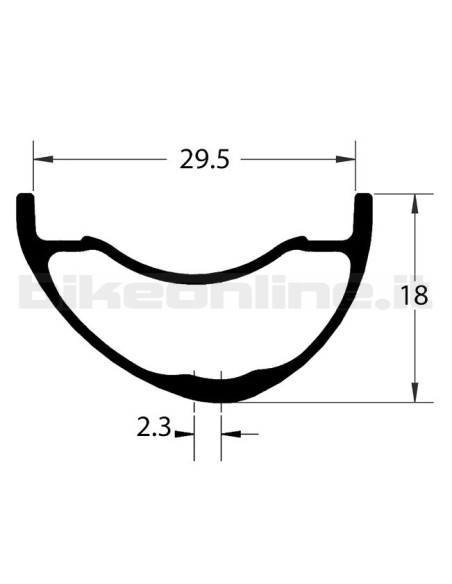

Inner width: 29.5mm

External width: 32.00mm

Rim height: 18mm

Number of holes: 28

Tubeless Rady: yes

recommended tire width: 2.0" - 2.6"

maximum tire pressure: 2.8 bar (2.25")

Finish: matte

Black colour

Weighed weight: 435g

Hub features:

EXTRALITE HYPERBOOST3 F - HYPERLEFTY3 front / HYPERBOOST3 R rear

Front available in Boost 15x110mm or Lefty 2.0/Supermax

Rear available in Boost 12x148mm through axle

Race-proof hyper-engineered rear disc hub.

Bearing options: 440C Stainless Steel, HDC Hybrid Ceramic, XD-15 Ceramic.

ABI Stainless cartridge bearings (2 front + 4 rear)with high load capacity & low friction RS seals plus external O-ring seals.

Oversized 17mm axle with external micro- tuner.

36-60p.o.e. front-engagement freewheel with long-life polyurethane lip-seal.

Black anodized body with laser etched graphics.

Flanges for straight-pull d/b spokes: 28H

Freewheel options: Sram XD (11-12s), Shimano MTB 11s, Shimano 12s compatible (includes special locking-ring)

Bearing options: 440C Stainless Steel, HDC Hybrid Ceramic, XD-15 Ceramic.

Internationl Standard 6 holes rotor fixing

Made in Italy

Weight: from 74g + 148g

Spoke features:

ALPINA BLADE SUPERLITE

Made in Italy by Alpina

Made with AISI 302 stainless steel through cold forging process.

Section: 2.0-0.9/2.2-2.0mm (bladed section is 0.9 x 2.2mm)

ALPINA BLADE HYPERLITE offer a significant weight saving with no loss of resistance, stiffness of the wheel and durability of the spokes

Section: 2.0-0.9/1.6-2.0mm (bladed section is 0.9 x 1.6mm)

Black colour

Every wheelset is supplied with 3 spare spokes/nipples

Nipples: Pillar DSN ergal acid green, black, blue, gold, green or red

Not supplied with quick releases

Our wheels are built by hand in house by highly specialized personnel.

The Bikeonline staff uses the best professional tools on the market into each step of the wheelbuilding process. The P&K Lie truing stand is one example, it allows us to check perfect truing through precise decimal comparators (0.1 millimeters accuracy).

We build most of the tools we use, to fit the level of our builds, which require a high accuracy.

The use of different tensiometers as Park Tool, Pillar and DT Swiss allows us to reach the correct tensions of every spokes.

Each wheel is pre-stressed by hand to ensure that nothing has been settling during the early stages of use and that the spoke tension remains constant for a long time even under very high loads

This product is to be considered produced on request / on order, due to the high customization needed. It is therefore not possible to use the right of withdrawal or the cancellation of an order already confirmed.

See "Terms and conditions of use". Advance payment is required on this product.