Enduro only uses 440C stainless steel balls and races to provide long life and superior corrosion resistance in applications and environments that may be less than ideal.

440C has the highest strength, hardness, and wear resistance of all the standard 440-series stainless alloys with high carbon content.

As expected it is also the most expensive of the 440 series alloys and requires multiple rounds of treatment processes to achieve its superior mechanical properties. Superior to the more commonly used 440A or 440B that other bearing manufacturers use interested in saving money, 440C stainless steel alloy has a higher Carbon content giving it maximum hardness and corrosion resistance after heat treatment and cryogenic treatment.

When the rain won’t go away, and your bicycle seems more often to be used as a boat rather than a bicycle, you may want to consider 440C stainless steel bearings. While not quite as hard as chromium bearing steel, 440C stainless steel is a good alternative in constant wet conditions, or where sweat and sticky drinks become a problem with components such as headset bearings and bottom brackets.

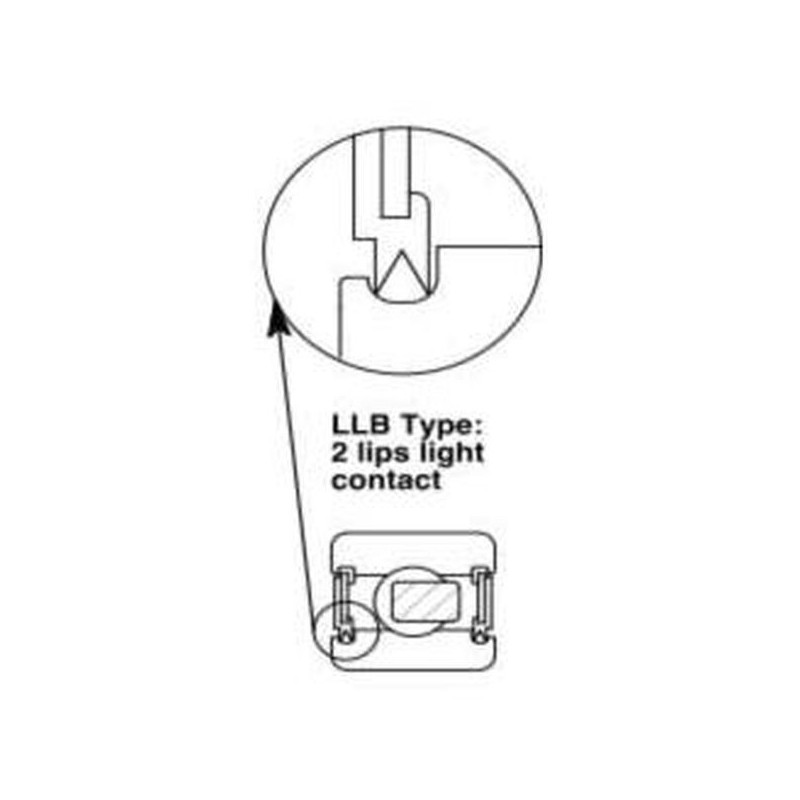

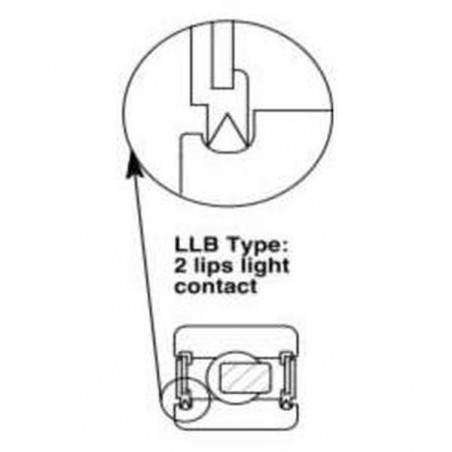

Enduro Bearings uses LLB type seals and CRC Marine Grease in our 440C Stainless Steel bearings to additionally water proof against the elements.

Balls:

440C Stainless Steel Balls are within 5/1,000,000″ round. These are military level specification, used for precision equipment. R-64 hardness, of the highest grade.

Also Races are made of 440c stainless steel, polished to a mirror finish for ABEC-5 precision and noiseless movement. Nylon with graphite retainers are virtually frictionless while providing constant lubrication

Races:

440C Stainless Steel Races

Vacuum de-gassed process for the purest chromium alloy steel, hardened to R-62, extremely tough and very durable. Polished to a mirror finish for ABEC-5 precision and noiseless movement.

Retainers:

Graphite/Nylon Ball Retainers

Nylon with graphite retainers are virtually frictionless while providing constant lubrication.

The ABEC-5 Standard:

To meet the ABEC-5 standard, bearing design must pass all tests, which include noise testing at high RPM, extremely close tolerances for I.D. and O.D., roundness of ball, trueness of the races and micro surface finishes of balls and races.

Seals:

Two NBR 70 rubber LLB Dual-Lip seals with low contact type seal, which rides in a matching groove machined into the bearing.